Nearly two years ago, Dana Bourgeois announced a formal partnership Eastman Instruments. It was a move that not many acoustic guitar fanatics saw coming: One of the world’s most cherished boutique acoustic brands (frequently seen in the hands of artists such as Sierra Hull, Bryan Sutton and Courtney Hartman) joining forces with an imported instrument juggernaut? How was that going to work out?

“So far, so good,” Dana tells me over Zoom. Finally, after a lengthy wait, guitarists are about get a glimpse of what’s been brewing.

Earlier this week, The Fretboard Journal launched its FJ Exclusives offerings with one of the early prototype OMs from this collaboration: Bourgeois’ Touchstone OM (along with a gorgeous FJ-red custom Calton Case). The instrument sold in about 30 seconds. (What can we say? Our readers are the best.) On the cusp of that, we spoke to Dana himself about the Touchstone guitar line (partially made in America, partially in Asia), what else we can expect (mandolins, anyone?), and a lot more. The entire interview with Dana can be heard during Fretboard Journal Podcast 333, but we transcribed the good stuff here for those of you who don’t have any long roadtrips or listening sessions in the near future.

Fretboard Journal: We wanted to touch base with you and hear about Bourgeois and Eastman working together. But we also wanted to check in with you on what the last year has been like for you. How have you been holding up?

Dana Bourgeois: It’s been challenging. Probably, like every other business, we’ve had to rethink how we do many of the things that used to just be normal, so to speak.

The beginning of the pandemic was the worst part, when the governor essentially quarantined the state. We shut down for six weeks. We essentially waited until everyone would get unemployment checks. We stayed open as long as we possibly could, so at least the employees were all taken care of during that time.

Then, there was the whole uncertainty of what we were going to come back to when we came back. Orders were canceled left and right. We’d just come back from NAMM, announcing our new partnership with Eastman. We’d taken on a number of Eastman’s better clients as dealers and taken new orders, mostly overseas. The real focus of our expansion has been overseas. Orders were dropping left and right.

Fortunately, Eastman basically said, “Just keep building guitars. Everything’s good. We’ll take care of them. Things will eventually right themselves.” As it turns out, things righted themselves kind of on their own. As you probably know from talking with everyone else, by the fall of last year, all of our orders were restored, and more orders came in.

It turned out that guitar playing was one of those things – like bicycling and camping – a pandemic pastime that kind of took off. You can order guitars online, you can entertain yourself and your pod with guitars. Because there were no concerts to go to, right?

There was a big hole in the supply chain, because we weren’t the only company who shut down. Pretty much everyone I know shut down for some amount of time. And then, demand kind of cascaded.

We are now back-ordered farther than we’ve ever been in our history. And we’ve grown about 30% from pre-pandemic times. So I guess it’s a silver lining story. Lots of angst and stress and anxiety in the front end of it, but eventually it kind of worked itself out.

Our biggest problem: Over the winter, when we had the big pandemic spike, we were very, very careful about following CDC guidelines. If someone woke up with a sore throat, or their body temperature was up a little bit, they had to get tested before they could come back into work.

People were very good about not cheating. However, there was a huge demand for testing at that time, so it could take a week to get test results back. Someone would wake up with this little sore throat or not feeling well and go out and get a test. And, by the next day, they’re feeling better and they’re sitting out of work for a week, waiting for their test result, so they could come back in. That happened a lot; we had a lot of unplanned absenteeism.

We only had a couple of actual COVID cases. And we think they were separate infections; we didn’t infect each other. We did a pretty good job keeping the workplace safe. Then, all of a sudden, vaccines came out, and it’s a whole new day. The next rolling challenge was people getting their vaccines scheduled, and then getting sick because of the vaccine.

I think we’re through all of that now.

Those were the challenges, but I would like to say production has kept steady. Even though we’ve added more capacity, in theory, we just haven’t had the steady manpower until recently. But I’m not complaining. All in all, I think we’ve done very well and we’re very thankful for the business that the pandemic has provided.

This is partly the pandemic [effect on] business, but Eastman has pretty much worldwide distribution, and they have helped us extend our reach into Asia and Europe. [It’s] very difficult for a small company to export if you don’t have lawyers on staff. Every country has different import/export laws you have to work out.

There are just so many barriers to jump through. [Eastman] has been through it all, they know how to do it. And they’ve not only helped us identify markets and clients in those markets, but actually get products into the market. That has been just a terrific boon to business, as well.

That’s a long-winded story, but that is, in a nutshell, what our experience has been.

About three years ago, we moved into a new shop. It’s an old textile building, Lewiston, Maine. I think there’s about a half a million square feet in this building. I’m going to guess that no more than 30% is occupied. So we found a first floor space with a large, adjacent unoccupied space, which we’re now moving into, little-by-little.

We keep adding, we keep building on rooms, adjacent to the facility that we’ve built. These old buildings were large, open caverns. To build guitars and have good climate control, you have to build a box inside a box, and then climate control it.

We’re trying to figure out exactly what our layout is going to be for the remaining available space. We’re both expanding production and also building parts that we ship to China. We’re actually exporting voiced guitar tops. That’s a whole separate operation.

Fretboard Journal: I’m hearing that you have this backlog to end all backlogs and I’m talking to you [via Zoom] while you’re sitting in what is presumably one of several wood storage rooms. Is all of the wood you’re ordering coming through to you? Are you struggling to have enough to meet the demand?

Dana Bourgeois: Well, yes and no. We’ve actually begun purchasing wood with Eastman. They will go in and they’ll order 500 of this, or 3,000 of that. They have suppliers all over the world. The worldwide market is very backed up right now. If you’re building guitars on a very large scale, it’s a real challenge to get Sitka spruce, Indian Rosewood, mahogany, ebony … the basic materials.

The very high-end stuff that we buy? We might make five Macassar ebony guitars here and we want only over-the-top, gorgeous, figured Macassar ebony. I don’t want to say the price doesn’t matter, it kind of does. But, if it’s a little more expensive than it was, there’s enough margin built in to these very high-end guitars to absorb that.

Sometimes we have a hard time buying something like a Madagascar rosewood. Typically, we have a couple of suppliers. We might use 60 sets a year in a normal year. [In the past], we would buy a year’s worth, or half a year’s worth. We’d go in and pick out sets from photos, that sort of thing.

Eastman has gone to one of our suppliers and bought 2,000 sets! And we’re picking 200 off the top [for Bourgeois], which is more than we’re going to use immediately, but that’s where the price break works well for both companies.

Things like that have ceased to become a problem. Rather than having to constantly maintain relatively small inventories of 50 different tonewoods, I would say that half of those now we can buy with Eastman and sort of piggy-back on their larger orders. Not all woods are quite going to work that way. If you buy 3,000 sets of Sitka Spruce in a pop, we can get a hundred of those will be stuff that we can use.

Fretboard Journal: So, what are the nuts and bolts of this partnership? Does all the wood end up in one place and then get sorted, with some going to China, and some going to Maine? Or vice-versa?

Dana Bourgeois: Now that we can get out and travel, we’re kind of going to the wood source. And it works out pretty well, because a lot of the suppliers are in the U.S. So, we can go and inspect a thousand sets of whatever that are going to China, and at the same time, pick out what we want for ourselves.

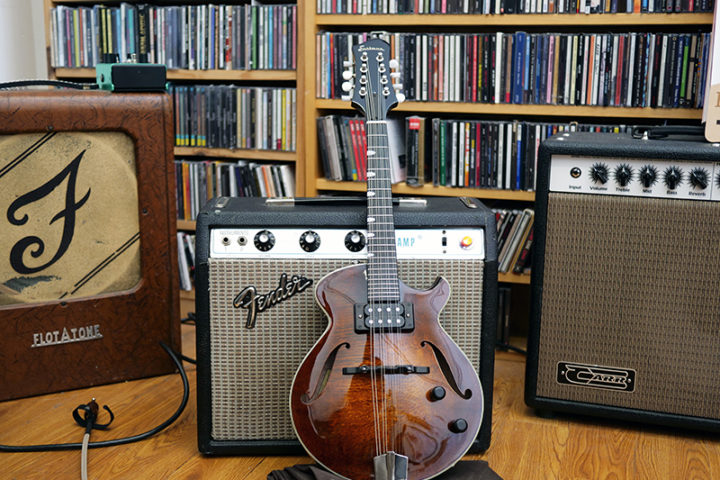

We’re planning a trip to Italy to buy spruce. Eastman is the largest violin family producer in the world. And they buy European maple. We’re going to be getting into mandolins, so all of that will be of interest to us.

Fretboard Journal: Is this breaking news? Bourgeois Mandolins? Did I get the scoop on that?

Dana Bourgeois: You got the scoop, buddy.

Fretboard Journal: Have you built many?

Dana Bourgeois: Not a lot of mandolins. We’re going to be starting off with mandolins that we have designed that will be built entirely by Eastman. We’re working on prototypes now.

Eastman bought a torrefaction kiln. So they can torrefy anything over there. They have the basic mandolin that’s totally designed by us. Eventually, we’ll probably make some mandolins over here. Right now, we’ve got our hands full. But we can make Bourgeois-branded mandolins, which we expect to. It looks like we’ll most definitely introduce next year.

Fretboard Journal: That’s exciting. I imagine when this deal was signed, you probably thought you were going to be going to China semi-regularly? How has this partnership turned out so far? What’s been surprising for you? Hearing you talk, I won’t say they’ve given you a blank check, but it sounds like it opened up some doors that maybe, as a mid-sized business owner, weren’t open for you two years ago.

Dana Bourgeois: That’s a really good description of how things have played out. Eastman is able to open up markets for us and help us acquire raw materials. They’ve also been able to help us fill in and expand our product line into price points that we frankly could never get into, unless you’re on a much larger scale, and everything’s automated.

So far, so good. They’re wonderful people to work with. We kind of hit it off, personally. It’s been liberating for me, because I get to dream stuff up and actually have it happen.

We’re planning for expansion of three times our size. That’ll be over several years. I would expect most of the expansion will be export. There certainly will be some expansion in the U.S. And the proposition is, “Okay, when you’re operating at this size, how do you want to build guitars? Break it down operation-by- operation. What’s the most efficient way of doing it?”

As a small shop, you rarely get the luxury of doing that sort of thing. I like to think that we have a few processes that we’ve developed, that are elegant and very efficient and unique. And we’re super proud of [them].

But then, [there are also] processes that are really dumb. And we do it this way just because it’s too hard to do it any other way, that sort of thing. You go to anyone’s shop and it’s kind of like that. Those dumb operations that some guy does by hand, hit or miss, in-between the hard way, just to get a part from here to here… they can go away if you’re building on a larger scale. All of a sudden, it makes sense. “Oh, wait a minute… this equipment would take care of it for us.”

[For example], the guy who’s been assembling necks for 10 years… our necks are CNC machined, certain areas are not perfect. He goes in, he quickly cleans them up by hand. But if that guy moves on and someone else takes that job, it’s like, “Oh, my God. This is a black hole! The new guy doesn’t know how to do this and it’ll take 10 years to learn to do it for the 20 different kinds of necks that we make.”

So, you go in and you re-draw your necks so that the shaping is perfect on the CNC. [It’s] a major project, actually, but we have now, access to scanning equipment and stuff like that, that’s actually going to make it doable.

That’s just one example. And if there are 1,000 steps to building a guitar, you go on each of those steps and say, “Well, there’s a way to do this better.” But you don’t have to do all of them. There are a few black holes in there, where you not only do you have to throw a lot of labor, but you’ve got to throw your best labor at it, to overcome.

Eastman has said, “Figure out how you want to do this for each operation, give us your report, give us a return on investment, what’s it going to cost, and we’ll break it into chunks.”

You can’t change everything at once. You can’t replace every component in your car at one time, while driving it, sort of thing. So, we’ll do a little bit now, a little bit later, and a little bit later. And we’ve actually already started, our chief projects are actually under way.

We hired two new engineers, so that this little engineering stuff doesn’t have to get done in someone’s spare time… designing the jig where you have the end piece inlaid, the little wedge at the back of the guitar, and how that jig is registered. We’ve known that there are better ways to do it than the way we’ve been doing it. It’s not exactly how we wanted to do it. [We] just never bothered to sort of put it all together.

Now, a new guy can come in and figure out how to do it within a reasonable amount of time. And then they’ll all come out pretty well.

Fretboard Journal: When you talk about expansion and eventually perhaps tripling your output in the foreign markets, where are the biggest opportunities globally?

Dana Bourgeois: Well, China is the biggest. The Chinese market for musical instruments is about the same size as the U.S. market.

Think of that for a minute. They have a billion more people. So it’s the tip of a pyramid kind of thing. Not everyone is a consumer of Western musical instruments. But those who are make up a market that is the size of the U.S. musical instrument market. That is a major area of expansion. And we’re only selling over-the-top high-end stuff there.

Fretboard Journal: For those of us who have never been, can you compare the two marketplaces? We’re used to buying a Bourgeois Guitar at a nice guitar store that often has mostly handmade guitars. And then maybe we’ll see [Bourgeois] at a bluegrass festival or jam. What is different and what is similar about the Chinese acoustic marketplace and how these guitars are getting played?

Dana Bourgeois: First of all, I’ve never been [to China]. Earlier, you asked a question about the back and forth. We had two visits between the time that we partnered with Eastman and the time that we shut down for COVID. We sent our production manager over to China to check out their operation. Their production manager came over twice.

We were planning monthly visits. Every other month, we’d go over there, and every other month, they’d come over here. Then, the whole thing shut down. In fact, Eastman’s owner, Qian Ni, who is an Americanized, Chinese-born gentleman, has been here through the pandemic.

I don’t know too much about what the retailers are like. I know they tend to be in the larger cities. They’re more boutiques. I’m not sure they have the equivalent of a Guitar Center in China.

From what we’ve heard, the dealers who we’ve had contact with seem to be high-end, more like what we’d find in Japan. There could be another level of dealership out there that I just haven’t dealt with yet. We’ve mostly specialized in really high-end stuff. Because we can’t do volume yet, we might as well do high-end stuff.

It’s a good way to establish a brand identity. The volume will be a little bit later down the line.

I do know that the demographic is different. The high-end buyers over here tend to be Boomers, retirement age, or plus-or-minus retirement age, kind of thing.

It’s a much younger guitar-playing population over there, 30s and 40s. We’re designing a Signature model guitar for a Chinese pop star, Xu Wei.

So, there’s a Chinese music market, I guess. He sounds like he’s pretty well-versed in Western pop music, and a pretty good guitar player, but mostly a singer. He plays acoustic guitar.

That’ll be a bit of a challenge to see how all of that works out. And I guess he has enough of a following so that the distributor, Eastman’s distributor in China, has said, “Let’s do a Signature model.”

It is strange to be building something for a different culture. The only Chinese pop music I’ve listened to is Xu Wei. And it certainly relates to Western pop music. I suppose if we build him the same kind of guitar that someone in Europe would be playing, if they sang in French, we could make it work.

Fretboard Journal: Could you envision a point in your company’s future where you’re voicing instruments specifically for Chinese marketplace versus what you presume will sell in America?

Dana Bourgeois: Who knows? It is the brave new world.

Fretboard Journal: Let’s switch gears for a second and talk about a specific project, the Touchstone OM 2. Can you walk me through the process of how this guitar got developed and how it’s actually going to be produced, just so folks can wrap their head around it?

Fretboard Journal: The concept is super cool, I think. We are building and voicing guitar tops over here in the U.S. and shipping them to China. They get built into bodies [and] strung up. The guitars get shipped back here for, just for quality control and to make sure the setup’s good. So, it’s a co-produced instrument.

In a way, I sort of came out of that world with Schoenberg Guitars. We supplied materials and parts to C.F. Martin, and they put together guitars under the Schoenberg name. I used to go down to Nazareth and actually voice a whole batch of guitars at a time while they were in construction in Nazareth.

I can’t quite do that that easily halfway around the world. But it’s a similar idea. I don’t want to say that all of the sound of the guitar comes from the top. But, certainly, it’s the most important part. And we have a system of voicing where we go to a certain level of flexibility, and we build to bring out a balanced response of top tones.

The formula works pretty well. We’ve received quite a few prototypes, and they’ve all sounded pretty dang good. The challenge has been to decide the rest of the guitar, and how it’s going to be built. They’ve actually built quite a few bodies already and we’re working on the final neck designs. And we’re expecting to be getting our first guitars before the end of the year [2021].

Things have been a little bit slow. If we had been able to go to China every other month and if they had been able to come over here every other month, it’d be a lot easier to say, “Okay. Here’s the little trick of how we put this together,” kind of thing. YouTube is banned over there. We can’t upload a video to YouTube. We can do a Teams, like a Zoom conference call. And if we want to show a video, we’ve actually been running the video on a screen up to a screen, to show how we do something. That’s been one of our workarounds.

They are on a major rebuilding over there. A lot of things are going digital. Our production manager came back and said, “You know what? Their guitars are more hand-built than ours!” Literally. Many things that we just do on CNC are done the old-school way, which is laying a pattern on something and cutting it out and sanding it to shape.

But they are very quickly transforming over to new methods of both making parts and finishing, a lot of CNC work. So, it took a while to even find a common language for CAD file. Because the stuff that they were using was different from what we were using.

Now, we’ve merged that and we have some common CAD language that we can use. They scan parts for us and send back scanned necks that we can play around with and edit. So, it’s been a really interesting process of learning to communicate. It’s been fun.

Fretboard Journal: It can’t be unnoticed how ironic it is that, while they’re helping you have the wherewithal to update all of your machinery and automation, they’re potentially more handmade on their end.

Dana Bourgeois: There’s a lot of weirdness about the term “handmade.” Ultimately, you have to know how to build a guitar, to design it, to be made on a CNC. Then, everything is finished by hand or assembled by hand. So, the question is: What’s the difference if you want to use a handsaw to cut a board to length, or do you want to use a table saw? How precise do you want these parts to be?

Fretboard Journal: Circling back, is Touchstone going to be the name for all of the collaboration guitars?

Dana Bourgeois: Yes. The Touchstone Series.

Fretboard Journal: And I’m guessing there’s sort of a dedicated team on that end. It’s not like somebody who was building a violin yesterday, is now building a Bourgeois Touchstone OM today. How does it work out?

Dana Bourgeois: They actually built a new workshop inside their facility. They’re building Bourgeois [Touchstone] Guitars there. And they’ll do some custom guitars there. But it was mostly built for this project.

Fretboard Journal: Incredible. When you try these guitars out, are they pretty much on point with the Lewiston OMs?

Dana Bourgeois: Our average guitar now sells for about $7,000. That’s the average; that’s not the median. These guitars are going to be in the mid twos. So, if they get even in the ballpark, they’re going to be a real bargain.

My whole thing is if they look aesthetically correct, if they play right, and if they sound good, it should be a bargain for the consumer. For years, we’ve tried to build a less expensive guitar using US labor and in small quantities.

You end up losing your shirt. But the downside of that is what percentage of all the guitar players in just the U.S. alone, can afford a Bourgeois Guitar?

It’s not just that it’s an elite kind of thing. It’s that we actually can’t interact with all of these players, because we have nothing for them. This is going to be a way to just expand our touch, so to speak.

Fretboard Journal: You mentioned mandolins, so I’m guessing you’re also thinking about stuff that wasn’t even on the table before now. Are you thinking about different models and shapes that might be part of this partnership that don’t exist right now in the domestic Bourgeois lineup?

Dana Bourgeois: On the guitar end? Not really. The first run of guitars will be OMs, dreadnoughts, and Grand Auditoriums in three different styles. It’ll take a little while to get all of those out. But it should happen pretty quickly once the first guitars get released.

Making variations should be easier. And then, I don’t know how long we’ll go with that. Certainly, you want to get to market. That’ll be the brand identity of the Touchstone Series. And then we can branch out from there. I would certainly want to do a new, like an L-00 and a Slope-shoulder dreadnought. Who knows where we go from there?

Fretboard Journal: When this partnership was announced, I’m sure some people thought that you might be planning an exit strategy or retiring. Are you actually working harder now than you were two years ago?

Dana Bourgeois: Yeah. Next week’s actually my first vacation since last summer. Let’s blame part of that on the pandemic. We certainly have a lot of irons in the fire. I have, for the first time, a real employment contract. And, back in 2019, I signed a five-year contract that would take me to age 72.

Now everyone’s saying, “You can’t just leave. What do you want to do when this is up?” I’m having the time of my life, really. Probably what I will do is stay involved in planning guitar design, wood purchasing, that sort of thing and dial it back to where it’s not necessarily an everyday kind of thing. But all the fun’s going to happen and the fun’s going to keep happening. I’ve spent my entire career sort of preparing for this.

Fretboard Journal: I’m hearing [you talk] about these guitars moving 8,000 or whatever miles away, back and forth. But could there be a point where these guitars are just made there?

Dana Bourgeois: I would hope so. We are working on devices that will give metrics or flexibility, that can be dialed in pretty carefully. Part of a lot of this is wood selection. A Lucchi meter will read the velocity of sound in any piece of wood and tell you, in theory, what’s a better piece of wood than another.

Certain kinds of wood [you’ll think] will make a really good flatpicking dreadnought, but it could make a really cool parlor guitar. They have different qualities. But the point is knowing enough to make the selection and the allocation. That kind of stuff can be done.

They were all over watching us voice. I’m not the only one who does the voicing. I’ve trained a couple other people here and go away for a period of time. If we’re building a guitar for Sierra Hull, I’m going to want to be there when it’s voiced. But for regular production, they do a good job. On any given week, it comes out as well as if I’ve done it.

So, yes, I think it’s transferable. We’re working on that. Does it mean that we don’t have to build guitars in Lewiston? I doubt it. A guitar is so much more than an object, as you know. It’s a cultural touchstone. That’s one of the reasons we use the word Touchstone.

A certain kind of guitar has so much cultural stuff to unpack. You see an old Martin, or a new Martin guitar, a Santa Cruz guitar, etc. [and] you think of all of the history of the influences. That’s the fun part of it. That’s what’s caught the imagination of the people who are our clients, at any rate.

I don’t think that ever goes away. It’s the same thing with violins. Violins are even more storied than guitars. Eastman makes so many cool things like brass instruments and woodwind instruments, flutes. And I’m starting to just pick up some of those vibes.

The Haynes Co. flute in Boston, which is the oldest American flute company, is part of the Eastman group. Talk to people from Haynes flute… they talk about the reverence they have for the European flute-makers that proceeded down the history of it, how things changed. They were responsible for these innovations, other people [were responsible for others]…

All of that matters. It’s part of the music. If you want the Dana Bourgeois Unified Theory of Everything: I’d wrap it up in a package that says, “Everything flows from the music.” That’s the part that we care about, the music that’s played on these instruments. And the instruments become part of the story of the music. And then the instruments have their own story.

It all adds to this incredible cultural richness. I like to think that we’re in the business of making people happy. Playing a guitar, or listening to someone play a guitar, all of this sort of transferred happiness part of it. The bottom line is that all of this little stuff matters. It all adds up to something.

So, will [Bourgeois] guitars only be made in China someday? Not really. Because the music that the guitars make is Western music, if you think about it. The reason the American guitar is still king in the world, even though other cultures … Japanese make beautiful instruments, the Germans make beautiful instruments… really well-crafted stuff.

But the Beatles played American guitars. It didn’t start with the Beatles. But, at least for our generation, you look at the Beatles as the starting point for popular music. And popular music spread around the world. Western popular music is enjoyed in some form by pretty much every culture in the world, including Xu Wei, the Chinese pop star. At the beginning, they all played an American guitar.